Quick Details

Place of Origin:China

Type: Aluminum alloys Ceramic Plates

Application:Industrial Ceramic

Material:Alumina Ceramic

Model Number:round, square

Processing Service:Moulding

Acid resistance:>99.6%

Channels Density:10~60 ppi

Porosity:80-90 %

Operation temp.(max):1100-1600°C

Bending Strength:0.6-1.0 Mpa

Size:Customized

MOQ:1 Cubic Meter

Feature:Heat Resistance

Supply Ability

3000 Cubic Meter/Cubic Meters per Month

Packaging & Delivery

Packaging Details Wooden Box

Port Shanghai / ningbo / any other port

Lead Time:

| Quantity(pieces) | 1 - 1 | >1 |

| Est. Time(days) | 7 | To be negotiated |

Product Overview

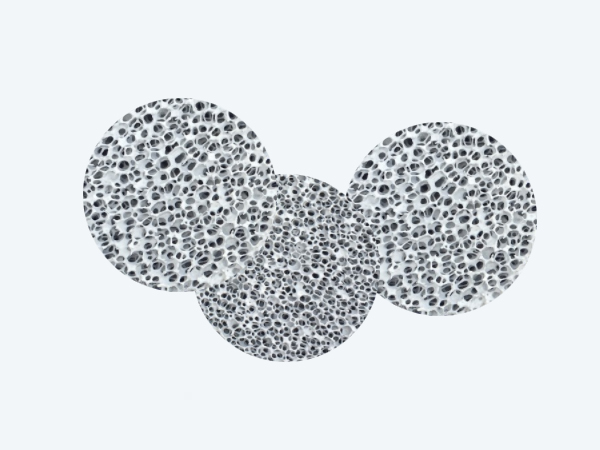

Alumina Porous Ceramic Foam Filter Plate for Foundry

Alumina ceramic foam filter is a new type of low density, high porosity and with three dimensional network skeleton structure of the filter. And widely used in aluminum process industry for molten aluminum filtering, so as to improve aluminum quality. Alumina ceramic foam filter can effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, to improve the quality of aluminum alloy and other non-ferrous alloy casting, all of which contribute to reduce casting cost, its maximum service temperature 1200° C.

Alumina ceramic foam filter has the advantages of high porosity, high mechanical strength, stable chemical property, strong corrosion-resistant, high adsorption rate, excellent filtering functions and thermal shock resistance. It is mainly used for purification process of aluminum, aluminum alloy, and other nonferrous alloy production, can also be used as gas-solid, liquid-solid separation medium, catalyst carrier, burner and sound-absorbing and environmental protection fields.